Ford Motor Company has announced the modernization of its Thailand manufacturing operations with a USD 900 million investment in new technologies and systems. This is the company’s largest-ever single investment in Thailand. Part of the Ford+ plan for growth and value creation, the investment supports the production of the next-gen Ranger pickup truck and Everest SUV.

The investment brings Ford’s cumulative investments in the country to more than USD 3.4 billion over 25 years. The modernization program bolsters Thailand’s role as a global production and export base for Ford, through its wholly-owned Ford Thailand Manufacturing (FTM) and joint-venture AutoAlliance Thailand (AAT) truck plant.

The addition of a second shift at FTM adds up to 1,250 incremental jobs, increasing Ford’s local workforce to more than 9,000 employees. Ford is also providing opportunities for its local supply chain partners with more than USD 400 million invested in the supply chain network to localize and enhance the quality of vehicle parts and design-related tools.

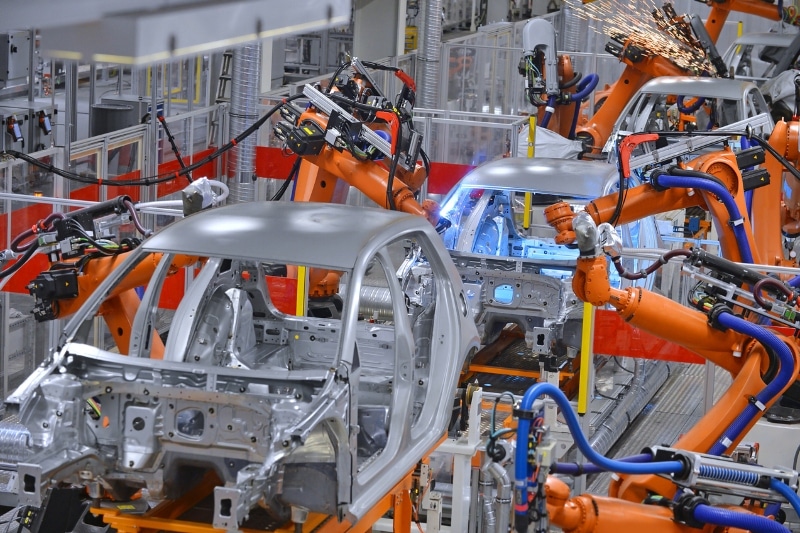

The company is almost doubling the number of robots at both FTM and AAT, with the addition of 356 state-of-the-art robots at the body shop and paint shop. As part of the investment, Ford is the first auto manufacturer to implement ScanBox technology in Southeast Asia. This latest surface scan capability improves the time used to accurately measure the whole vehicle by five times during the assembly process, helping Ford to increase efficiency in problem-solving for better quality control. Ford also has increased its production capability for multi-variant truck production in FTM. In addition, FTM and AAT are making efforts to support environmentally friendly initiatives, including using renewable energy, reducing CO2 emissions, and practicing zero waste to landfill.

(Sources: Ford; Bangkok Post)